24/08/2008

- Finished remaining drilling and dimpling of right aileron

As per

the pictures on the 22nd, the right aileron needed the same

treatment. So all the remaining parts for the ailerons have

been sent for priming

24/08/2008

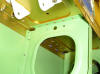

- Riveted on the

leading edge of the left wing

I was

nervous about this stage but the time had come. Some

builders struggle with solid rivets others use blind rivets.

The plans call for solid (though Vans underwrite the blind ones

anyway). I decided on a compromise that the outside rib and

innermost rib would at least be solid and the rest could be blind.

Shock

of all shocks, after making sure protective tape, the riveting

tool was appropriately ground down and then protected with a

plastic soc and that ground to the same shape the first rib, the

innermost one went very well indeed.

So the

decision was to do solid rivets all the way along. The one

right in the middle took three of us. One on the hammer, one

on the bucking bar, one with a torch and was the eyes of the man

on the bucking bar from the other end as he could not see if he

was upright on the end of the rivet or not.

We had

one problem with one rib which was the 2nd one in from the

outboard end and the rivets kept toppling over and making a mess.

After discussion Ian said the rivets are too long (we were using

the ones the plans stated) but he was right, when we dropped a

size everything was working as well as the others. The

result is 5 very good ribs with solid rivets and one rib ok with

solid rivets. Given some of the picture I have seen I am

really pleased with the results.

There was still enough time in the day to rivet all the skin to

spar rivets with the squeezer and put one skin back on to test the

result. Chuffed, a great day in the shop.